The Evolution of the U.S. Ginning Industry

If Eli Whitney could walk into a modern cotton gin, he might have a hard time recognizing his contribution to the industry. But he would probably also be fascinated with its evolution, speed and efficiency.

Much like the production side of cotton, ginners throughout the U.S. have experienced their own ups and downs over the past few years, thanks to fluctuating cotton acres, safety regulations, labor issues and continuing changes in technology. Some gins were lost in the process due to closures and consolidations. But what’s emerged is a stronger, more efficient – and safer – industry.

“We’ve had a tremendous amount of consolidation over the last 10-to-15 years,” said Harrison Ashley, executive vice president of the National Cotton Ginners Association. “We created larger gins that have the ability to gin greater volumes of cotton. And a lot of that was driven by technological advances at the gin level, as they put their resources together to gain efficiencies and economies of scale.”

According to the most recent National Agricultural Statistics Service (NASS) survey, 671 cotton gins are now operating in the U.S. That number has decreased significantly over the past two decades, but certainly reflects the trends in consolidation.

“We’ve had a number of gins that consolidated, plus a few new gins that have come in with the highest technology available,” stated Tim Price, executive vice president of Southern Cotton Ginners Association. “Surprisingly, the decline in gins has not been directly correlated with an increase or decrease in cotton acreage. That’s just not happening.”

A Fresh Start

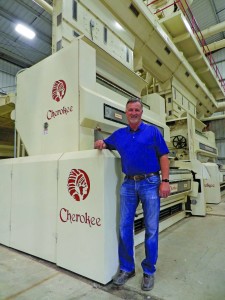

Perhaps there’s no better example of Price’s statement than a brand new, state of the art gin located in tiny Malden, MO. The gin opened its doors with brand new ginning equipment from Cherokee prior to the 2012 harvest – in a year in which cotton acreage in the Mid-South had dropped dramatically below historical averages.

Gin owner Bruce Dawson says he wasn’t scared away by dwindling acreage in the area when he decided to open a brand new gin last year. He had ginned in previous years with partners who, over time, began planting less and less cotton on their own acreage. Eventually, he decided to begin anew with his own ginning business, which he named after a gin his father once partially owned – the Bernie Farmers Gin.

Dawson believes the biggest problem hounding cotton acreage in his corner of the Mid-South is herbicide resistant weeds.

“With corn or beans, you don’t have to work so hard to deal with this resistant pigweed,” says Dawson, from the office of his new gin. “We’ve just had a struggle. People are tired of all the extra effort you have to put into keeping a cotton field clean, when you don’t have that issue with corn or soybeans.

“Weed control is by far the biggest problem we’ve got with trying to get people interested in planting cotton.”

Located in the middle of the Missouri Bootheel, Malden and the surrounding areas are known to produce high yielding cotton fields. This is one of the reasons Dawson is confident cotton acres will remain in the area and ultimately make a larger comeback.

Other sources of optimism are the advancements in weed control which will be introduced to the cotton industry in coming years. Monsanto and Dow are both gearing up to introduce new herbicide resistant cotton traits in the next few years to help combat glyphosate resistance. This will be in addition to Bayer CropScience’s Liberty technology, which is gaining popularity throughout the Cotton Belt.

“With the new weed technology coming, people are really looking forward to being able to use that,” Dawson says. “The key is trying to keep too many farmers from abandoning ship in the time before those technologies get here.”

Just like in the ginning industry, cotton farms have seen a good deal of consolidation recently. Subsequently, the average farm today is much larger than it was 10 years ago. An unwanted by-product of that trend, according to Dawson, is that gins take a larger hit whenever one farmer decides to pull out of cotton. Of course, gin consolidation can have the opposite effect.

As is the case with gins throughout the Cotton Belt, Bernie Farmers Gin has been the beneficiary of other gin closings in the area. Dawson says the gins that have survived acreage reductions in the Mid-South are oftentimes ginning more than they ever have, due to consolidation.

According to Ashley, when gins consolidate, many have been able to upgrade to newer technology such as monitoring systems to help reduce energy costs and automated systems for tasks like handling modules and strapping and bagging finished bales. At a minimum, gins must meet all OSHA requirements, plus additional requirements in some states that are more stringent than the federal standards. This can include air quality regulations, which may require extensive emission control equipment.

“All of our regional associations have safety specialists and programs in place,” reported Ashley. “With the emphasis we place on safety and training, we have reduced the number of incidences regarding injuries in cotton gins. We want to keep our workers safe, and we’re doing everything we can to adhere to all state and federal rules and regulations.”

The new ginning technologies have made the process faster and simpler. But it’s also true that the value of increased automation may have as much to do with labor shortages as it does with efficiency.

“Labor is one of the highest costs a gin faces, in terms of wages and things like insurance and injuries,” stated Dusty Findley, chief executive officer of Southeastern Cotton Ginners. “The crackdown in immigration over the last couple of years has made labor harder to come by, both local and migrant, and most gins are trying to focus on how are they going to do the job they have to do with fewer people. By necessity, they’re trying to find more efficient ways to do things.”

Many eyes within the industry are currently focused on Washington, DC and the debate on immigration reform for guidance and clarification on labor issues. According to Findley, an alarming percentage of legal labor has already moved out of most Southeastern states, and ginners are scrambling to find people to work.

“What is being discussed in Washington in terms of immigration has a two-tier visa system for ag workers who remain in agriculture,” explained Ashley. “This workable guest worker-type program is something that ginners and farmers have been wanting. It would replace the current H-2A program, which we have not been able to use to the extent we would like. If the immigration reform bill does pass, this will be a part of it and something that ginners will be able to utilize even more.”

The immigration proposals also include a provision for a delayed E-Verify-type system for agriculture that will be put in place within several years of passage.

Yet for an industry facing labor shortages and decreased acres due to crop shifts, drought and other factors, the ability of ginners to adapt and evolve is nothing short of amazing.

“We’ve seen a tremendous amount of grower involvement in gin ownership,” pointed out Ashley. “If you look across the Cotton Belt, more and more gins are owned by producers. If a producer is involved in a gin, they should know more about what’s going on in that gin in terms of quality. And that should translate to growers picking varieties that produce better fiber qualities.”

Price agrees, but also points out other emerging trends in gin operations.

“A lot of gins have vertically integrated into not only cotton production, but also into warehousing and cottonseed storage,” he said. “Those have become additional areas for profitability and sustainability. And we’ve seen a rapid expansion of module systems, which are impacting everything from handling to transportation.”

The new modules, especially the round modules, have helped solve some transportation issues and opened up gins to take cotton from greater distances.

“We’ve traditionally had problems with module trucks and regulations on roads,” explained Findley. “With the round modules, there are ways of handling them with flatbed trailers or other trailers rather than a module truck that’s oversized. We can haul them legally for greater distances.”

Growing Optimism

Even with the changes and challenges within the ginning industry, optimism among ginners remains high. In the Missouri Bootheel, Dawson says there are adjustments that can be made to help his new gin navigate the lean years – if and when they come.

“There are things we can do, as far as managing staff more efficiently and things like that, to help us get through a tough year,” Dawson says. “And the price of cottonseed has helped us and can continue to help us.”

Ultimately, Dawson believes the success of his gin relies on increased cotton acreage – or at least in stemming the decline of cotton acreage in his area. Maybe the most important factor to help that cause, he says, is that farmers would rather grow cotton – if all other things are equal.

“If we could get our weed control issue resolved, there will be a lot more cotton grown in this area,” Dawson says. “It’s a good cotton growing area, and we really can yield well. As long as the price is competitive at all, there will be a lot of cotton here, because these guys would just prefer to grow cotton.”

If and when the day comes that growers have a better handle on their weed problems, and acreage subsequently returns, Dawson says he’ll be well-positioned to take advantage. Nationally, leaders within the ginning organizations say they have heard a similar sense of optimism from their ginner members.

“Just about everyone I’ve talked to in the last month or two has been positive in terms of attitude,” said Findley. “That’s not what we would have expected six months ago. We got some acres back that we thought we were going to lose. We also had a drop in acres last year, but the yields were so good that it gives everyone hope that they can still make a decent crop and make some money.”

“While all of these changes are taking place, we still see a love for growing cotton,” added Price. “Cotton can still be a long term viable part of the Mid-South crop mix.

But we have to remember that the market is king. Some years, the market says you’re going to do well and some years, you’re going to be challenged.”